RADAN | Designer – a Specialist Sheet Metal CAD for CAM – Launches with new RADAN

Endless Nesting Workflow, Enhanced Common Cutting, and Faster Quotes

A new piece of specialist CAD for CAM software specifically for sheet metal has been launched alongside the latest release of RADAN.

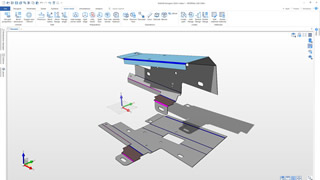

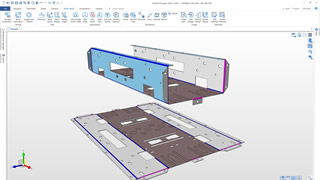

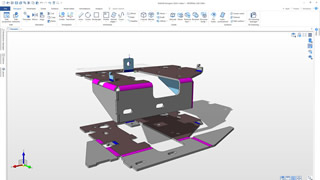

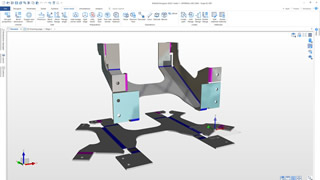

RADAN | Designer will form a pivotal part of RADAN’s CAD/CAM functionality in preparing parts for bending, nesting and cutting. From model design to part repair and modification, it is said to be the ultimate solution for taking geometry through to manufacture.

While the module is available on the new RADAN 2020.1 pricelist, existing RADAN 3D users have the option of a free upgrade. Product Manager Olaf Körner says it contains a material library and several calculation methods to create the correct unfolded shape. “Unfolding parameters such as bend allowances, can be controlled independently of the geometry, leading to more accurate flat blanks, more accurate folding, and ultimately, to a higher quality product.”

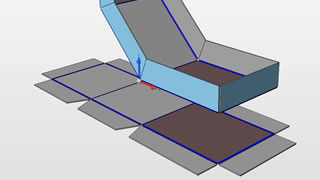

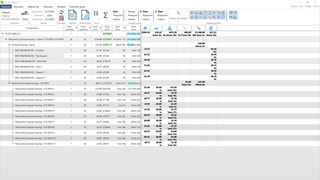

A major innovation in RADAN 2020.1 allows for an endless nesting workflow. Olaf Körner describes nesting in previous releases as being a snapshot. “The operator had a list of parts to produce, and cleaned up the workspace once the nests were finished. They started, finished, cleaned up the workspace and started the next job.”

Now, the new release delivers a more flexible, fluent approach, by enabling parts for additional jobs to continuously go on to the nest, which he says leads to improved machine and sheet utilisation. “It means manufacturers can react to changing priorities. They can simply add more parts without having to clean up the workspace, so the nesting process, and production, keeps going with no interruption.”

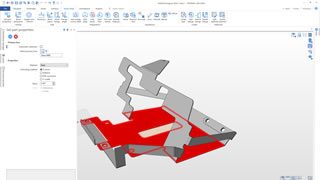

As common cutting is becoming increasingly popular, RADAN’s support for it has been extended with a new Common Grid Cutting algorithm. “Where there’s a nest of similar parts laid out in a uniform grid, we’ve optimised the sequence to do the common line cuts first, and then once around the perimeter, instead of beginning with the outside cuts. It’s a much more effective way of working, both for pairs of parts and larger grids. The risk of tipping is considerably reduced, and the heat build-up is more predictable.”

An additional safety check has been added to detect floating scrap in punching programs. The high level of automation, coupled with a target of not leaving anything on the machine, means programs are becoming more complex to ensure that everything’s either destroyed or removed. “If there’s anything wrong in the sequence, or applied tooling, that might generate floating scrap, RADAN 2020.1 now clearly highlights it.”

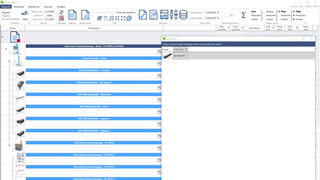

Four significant items of new functionality have been added to the Radtube module. Firstly, with information to feed nesters increasingly coming from ERP systems, Radtube can now use CSV files which specify the name of the product, quantity, and other parameters, negating the need to key them in again. Secondly, colour coding of specific parts ensures quick identification. This runs through from the design stage and set-up sheet, so the part can be identified immediately the machine has finished cutting, so the operator doesn’t have to rely on recognising it by shape or size.

The other two items follow on from that and are also linked to identification: improved reporting so that documentation going to the shop floor includes the colour coordination, and introducing a simple line font, instead of a more intricate TrueType font for text marking and imprinting parts.

In the previous release of RADAN, an option was introduced to import 3D files into Radquote, but they had to be single part files. In 2020.1 any multi-body or assembly files can be added. “For example, a complete SolidWorks assembly can simply be dropped into Radquote, which then unfolds all the sheet metal parts and calculates cycle times, to prepare an accurate quote.”

Improved support for bars and tubes includes the ability to set up a complete library of shapes for cutting – not only traditional shapes such as box sections, rectangular and round tubes, I-beams and C-beams, but also custom designs. “These can be defined and held in Radquote, ready for use when pricing a job.” And as nesting technologies and cycle times are the same for tubes as for 2D, Radquote can provide an accurate cost related to high performance nesting of bars and tubes.

RADAN’s powerful connection with WORKPLAN, Hexagon Production Software’s intelligent project management solution, has been enhanced, both in terms of quoting and nesting. WORKPLAN utilises Radquote to build prices with material costs and production times. It also offers a simple and efficient stock management solution for sheet metal nests, including stock reception/withdrawal, inventory, scrap management and part traceability. Interfaced with RADAN’s CAM programming, data reporting in WORKPLAN and deduction of sheets used, is all readily visible.

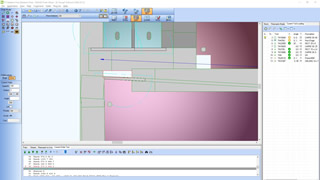

Finally, Radbend has been stronger in dealing with programming press brakes for multiple machines, by automating some of the steps. Where tooling is compatible, the time taken to switch a program from one machine to another has been reduced to around 30 per cent of what it used to be. Other improvements include improved workflows. “For example, if there’s a potential collision, Radbend not only notifies the user, but also remembers the action taken when calculating for collisions on an alternative press brake. It’s all about getting to the end result with shorter steps.”

In conclusion, Olaf Körner highlights that RADAN’s roadmap continues to bring all aspects of the software closer together. “For example, 2D nesting and tube nesting have very similar properties; Radquote is becoming as popular in quoting for tube contracts as for sheet metal; and the endless nesting workflow can be used just as effectively for Radtube as flat blanks. It reduces the time required to prepare a quote to around a fifth of what it used to be.”

“While there are many different things to consider, the final result is driving the manufacturing processes in the most efficient and profitable way. RADAN pulls everything together…and nowadays, all those aspects are merging.”