A continuación encontrará toda la información detallada de las últimas versiones de RADAN con las mejoras y nuevas funcionalidades introducidas:

RADAN Versión 2021.0

RADAN Version 2021

CAD/CAM

RADAN 2021 da un paso importante para los fabricantes que utilizan máquinas de punzonado y que quieren optimizar lotes de nestings. Ahora es posible usar Radnest Ultimate en el punzonado.

La optimización de los nestings con este nuevo módulo, puede reducir el número de chapas de materia prima en un ocho por ciento anualmente.

La configuración de las chapas ahora se puede generar y enviar automáticamente a cada máquina, ahorrando alrededor de 50 minutos de promedio en un día de producción de 80 nestings. Los programas CNC para el trabajo y las hojas de taller, van directamente a la máquina para el operador.

Radm-ax/Radtube

La versión 2021 corrige el problema en los agujeros peligrosos, creados cuando las piezas se dejan en una posición peligrosa después de que se ha cortado un agujero en un tubo. Ahora se pueden llevar a cabo cortes adicionales en los agujeros, dividiéndolos en trozos más pequeños que caen fácilmente.

Tres actualizaciones importantes para el nesting de varias piezas:

- La capacidad de importar números de pedido y de trabajo, que incluyen detalles de a qué orden pertenecen las piezas, por lo que se pueden mantener juntas para el montaje. "Significa que todo se puede rastrear a través del taller." Esto se logra a través de la importación CSV o mediante la modificación manual de datos en el multinester.

- Ahora es posible comenzar a fabricar automáticamente desde un ensamblaje completo, sin necesidad de tener en cuenta formas, tamaños o materiales individuales. Todo se calcula automáticamente a partir del ensamblaje, directamente en el motor de nesting con el número de pedido y de trabajo.

- Se ha añadido un nuevo informe de compras de tubos, que detalla qué materiales se requieren para un trabajo, ya sea desde stock o que deban ser comprados.

El corte común ahora se puede llevar a cabo incluso si los extremos tienen cortes en el diseño. Dos cortes superpuestos se pueden convertir en una secuencia de corte común donde se cumplen dos aspectos específicos; en primer lugar, las entidades finales deben producirse con un solo corte; y en segundo lugar, los recortes finales deben superponerse al menos en un 25 por ciento. Esto significa que ahora se pueden considerar hasta tres cuartas partes de todas las piezas de tubo para el corte común.

Radbend

Una nueva opción mejora el análisis de colisiones durante la secuenciación automática. Esto es particularmente valioso cuando se doblan piezas largas y delgadas, como canalones.

Radbend ahora reduce el manejo al calcular secuencias automáticamente, al disminuir la necesidad de rotaciones de herramientas y piezas. Cada vez que los operadores tienen que dar la vuelta a una pieza, ya sea por sí mismos o con un compañero, toma su tiempo. Esta nueva funcionalidad calcula una mejor secuencia, lo que significa que se puede introducir en la máquina con pocos pasos, mejorando el manejo.

Y el editor de herramientas ahora muestra información adicional importante de forma predeterminada, por lo que es más fácil de usar.

Radquote

En Radquote, ahora se pueden especificar las estrategias de corte en una pieza. El sistema nos preguntará cómo se van a cortar las piezas (Oxigeno, Nitrógeno, etc.).

Los archivos de dibujo RADAN 3D se pueden añadir a la oferta, complementando su capacidad de leer directamente desde archivos CAD creados por sistemas como SolidWorks, Inventor, Creo y Catia.

Un dibujo 2D se puede modificar rápidamente en Radraft y actualizarse en Radquote. Algunos sistemas de cotización en el mercado no pueden cambiar fácilmente una pieza gráficamente. El beneficio de esta mejora de Radquote, es que si usted ha recibido un archivo que no es 100 por cien preciso se puede editar fácilmente en Radraft y el archivo actualizado es leído por Radquote.

RADAN | Designer

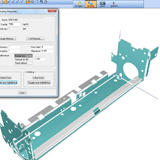

Se han añadido varios elementos de funcionalidad nueva y mejorada al módulo Designer, incluidas "mejoras espectaculares" para enviar el diseño terminado al CAM.

Hay seis formas diferentes de enviar datos de Designer a RADAN CAD/CAM, incluido el envío de patrones planos de todas las piezas que se van a agregar a un proyecto de nesting y el envío de una sola pieza para abrir geometría en el editor de piezas. Designer ahora indica pliegues donde el radio de diseño difiere del radio de resultado esperado cuando se utiliza el ancho V como método de desplegado. Esto es importante para el proceso de desplegado y el acabado del componente.

Ahora se proporcionan comentarios sobre los despliegues superpuestos. A veces, cuando se despliega un modelo 3D, no funciona: las caras chocan una encima de la otra. Ahora se notifica al usuario de esto y se muestra el problema gráficamente.

Otra nueva función añade desahogos estancos, mostrando en 2D lo que se verá para hacer en 3D. Y el comando dividir cara ahora puede tratar arcos, lo que hace que sea más rápido abrir un borde cerrado.

RADAN Versión 2020.1

RADAN Version 2020.1

RADAN

Nesting Workflow

RADAN 2020.1 builds on the existing workflow for nesting to potentially work endlessly – nesting is a constant flow of part requirements coming into the system and nests flowing on to the shop floor. This release focuses on feedback from the shop floor about when a nest is cut on a machine.

Common Grid Cutting

Requests to make the processing of regular grids more efficient have been addressed with adaptations to auto-tooling which detect and improve the tooling and sequencing applied to regular grids of parts.

Floating Scrap Test

Order mode has a new button to make it easy to check for floating scrap. Any points in the sequence where floating scrap is detected is highlighted, as well as the area on the sheet that is affected.

RADAN | Radm-ax/Radtube

Simple Line Font for Etching

A new, simple, single line font is now available which is not decorative, but clear and simple to etch.

Simple Font is the default font for use when adding text features. You can use the Choose button to select any font you have installed.

Enhancements to Imprint 2

Support for tenons was added a few releases ago which created tabs and slots for positive alignment, but these are not always suitable. Radtube 2020.1 offers a simple and quick way to provide guide marks on parts. Imprinting function now allows edges of one part to create lines on a neighbouring part which could then be etched to provide the visual clue required.

Cut Sorting

Cut sorting options are now part of the Auto Cut process. This allows users to choose the cut sort method to apply during the tooling process rather than as a secondary task. Optionally, users can set the desired sort method, then choose not to show that screen to enforce a consistent sort method for all following jobs.

Nesting CAD Files Without Tooling

Multi-nest can now work with Parasolid files (x_t or x_b file extension) which can be created from many CAD packages. After nesting the parts will be automatically cut.

Material information is not available from the source files, this can be specified before proceeding; the shapes, however, are detected automatically.

Import Nest Details from a File

Production details can now be imported from a file with a specific format to populate the Multi-nester. The file must contain 4 columns of data separated by semi-colons ";".

Coloured Parts

Parts can now be coloured for easier identification. The selected colour will be used in all nests that contain the part. The colours are also shown on the reports.

RADAN | Radbend

Programming for Multiple Press Brakes

A new checkbutton menu option under the menu Machine->Switch to other pressbrake to automatically rearrange and/or realign the toolsetups when switching to a different pressbrake.

Usually if you switch to another pressbrake, the other pressbrake has a different size and the tools are no longer in a default position (generally the middle) of that pressbrake.

If the menu option Rearrange toolsetups on switch to other pressbrake is on, while switching to a different pressbrake, the toolsetups will be rearranged and realigned according to the tool selection options for the new pressbrake.

If the menu option Realign toolsetups on switch to other pressbrake is on, while switching to a different pressbrake, the toolsetups will automatically be realigned according to the tool selection options for the new pressbrake.

Properties Menu when Generating NC Code

The part properties menu is now shown on each compile.

This allows users to change program or NC name or number or Comments while compiling without having to go to Program -> properties menu first. Furthermore, the Enter key will save the file and part properties.

Show Dimensions in Section View

The section view will now display dimensions by default; the user can still switch it on or off in the tree structure.

RADAN | Radquote

Import 3D Assemblies

Radquote can now automatically process 3D sheet metal assemblies from SolidWorks, Inventor, SAT and STEP.

Bars and Tubes

Shapes

Radquote now allows any shape of bar or tube to be defined as a standard shape. A shape can have any number of dimensions which define its characteristics; this can range from an inner/outer diameter and a thickness to width, height, radii and thickness. Radquote holds values for linear density, cross section area and surface per linear metre.

Quoting

Standard lengths are used when calculating material costs for bars and tubes; Radquote uses RADAN’s powerful nester to calculate the material cost.

The material use page now also shows a detailed overview of the material cost calculation.

RADAN | Designer

RADAN | Designer 2020.1 is a new application in RADAN’s product portfolio.

RADAN | Designer forms a pivotal part of our CAD CAM solution, preparing parts for bending, nesting and cutting. From model design, to part repair and modification, RADAN | Designer is the ultimate CAD solution for taking geometry through to manufacture.

Unfold Preparation

Several powerful sheet metal functions area available to prepare a part for unfolding. RADAN | Designer has functionality to correct the thickness, change bend radii and make changes to flange angles and lengths.

Unfolding

Unfolding a sheet metal part couldn’t be easier. RADAN | Designer offers a flexible material library and several calculation methods to create the correct unfolded shape. Available are unfolding using a setback at 90 degrees, a k-factor, DIN correction, or using only the V-width of the die that is used to bend the part.

Unfolding parameters, such as bend allowances, can be controlled independently of the geometry, enabling an accurate development that is based on actual bending machines and tooling to be used in production. This leads to more accurate flat blanks, more accurate folding and ultimately, a higher quality product.

Extensive Range of CAD Interfaces

RADAN | Designer imports data from a wide variety of exchange formats including Parasolid, IGES, STEP, ACIS, DXF, DWG, STL and VDA files as well as native data from the following CAD systems:

- Catia V4 & V5

- Pro/ENGINEER & PTC Creo

- Autodesk Inventor

- Siemens NX

- SolidWorks

- Solid Edge

The extensive range of translators ensures that users can work with data from almost any supplier. Very large files can be handled with ease and companies working with complex designs will benefit from the simplicity with which their customer’s CAD data can be manipulated.

Model Modification

The sheet metal part can be modified by adding bends, opening closed edges, splitting faces and creating corner clearances using powerful and intuitive workflows.

Working With 2D Data

RADAN | Designer supports the import of DXF and DWG files allowing the user to transform existing 2D data into a 3D model by simply reusing the imported profiles from the original data. Imported data automatically creates sketch profile regions making the transformation from 2D to 3D easier than ever.

Direct Modelling

Direct modelling frees the user from the constraints of a traditional modelling system. Rather than modifying a lengthy series of parameters to make a design change, direct modelling allows the user to push, pull and drag the geometry to obtain their desired shape. These changes can be completely freeform or driven by numeric increments and measurements taken from existing geometry. Knowledge of how the original model was constructed is no longer necessary and design changes are not constrained to the original methods of creation. Direct modelling gives the user complete freedom of construction whether creating a new component or modifying an existing design created in any of the myriad of CAD formats that EDGECAM | RADAN | Designer supports.

RADAN Versión 2020.0

RADAN Version 2020.0

General

RADAN CADCAM 2020 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD | Import and Export

This version of the software supports import of Inventor 2019, Solid Edge 2019 (ST11), SolidWorks 2019.

RADAN CADCAM | Nesting Workflow

All users who use RADAN to create nests now benefit from the more visual nesting environment that nest projects offer – but without the upfront setup this used to require. Now, as soon as the user enters nest mode, the familiar nest projects interface layout appears.

RADAN CADCAM | Project Templates

Nest projects and project templates can now be machine specific making it even easier to create a new nest or switch from nesting for one machine to another.

RADAN CADCAM | Importing Existing Nests

Users can now import existing nests into their nest project to make use of work that has already done.

RADAN CADCAM | Single Part Layout

RADAN 2020 makes it very easy to combine the rich user experience of nest projects with the flexibility and speed of single part layout as a nesting method. Whether the parts are already in the nest project or not, the user never breaks their flow.

RADAN CADCAM | New Punching Tool Type

A new punching tool type has been added to support ‘flattening tools’.

RADAN CADCAM | Configure

The Configure menu is now available in more modes, making it faster to access machine settings or to change the active machine tool.

RADAN | Radbend – Intermediate Bends

Intermediate bends are bend operations that are split up in two steps, where the start/end bend operation is split up again. They can now be used to solve challenging bends like hems.

RADAN | Radbend – Holes Near Bends

A new option will check for holes near bends in the clamp position phase while checking for collisions in background or in full simulation and act as any other collision check (which can be ignored or cause the batch process to fail).

RADAN | Radtube – Common Cutting

When legacy parts are opened, and they do not have the Common Line Cutting flags set, they are now automatically marked if the ends are suitable for common cutting.

RADAN | Radtube – Multinest Optimisation

A new control is now available when using Multinest that allows the user to optimise for time or material usage.

RADAN | Radtube – Reporting

Radtube now uses the same standard reporting tool as the other RADAN products, allowing access to charting tools, QR codes, etc.

RADAN | Radquote – Material Calculations

Radquote 2020.0 now uses the new nesting engine to calculate the material utilisation of irregularly shaped parts, increasing the change of winning the order. No user setting is required.

RADAN | Radquote – Automatic Export of Order Information

Radquote can be configured to automatically export information if a quote is turned into an order. The export formats available are:

- Comma delimited (.CSV)

- Plain text (.TXT)

- Excel (.XLS or .XLSX)

RADAN | Radquote – 3D File Support

Radquote now automatically imports and unfolds 3D parts ready for quoting.

RADAN Versión 2019 R1

RADAN Version 2019 R1

Radquote | Access

A significant update in RADAN 2019 R1 makes the popular Radquote function easily accessible to different categories of employees. Radquote users are generally not the staff who program machine tools with RADAN. So Radquote is made completely standalone and easy to use by anyone – automatically using machine technology for the quote, with Radquote calculating the accurate cycle time and the best material usage. This achieves an accurate quote every time, providing consistency and transparency, irrespective of who is producing the quote.

Radquote | Quoting Aspects

Radquote not only competitively calculates costing on sheet metal, but all aspects of quoting are now included – such as cutting, bending, welding, painting and assembly.

It’s also been enhanced to effectively deal with DXF files and also, soon, 3D files, as well as geometry that hasn’t been created yet. For example, if a component contains a number of holes, Radquote can produce a quote based on that information, without needing to know exactly where the holes are.

Radquote | ERP Systems

Radquote also links seamlessly with most ERP systems, particularly WORKPLAN. This means that if there’s a material price rise recorded in the ERP system, Radquote will utilise that information.

RADAN CAD/CAM Enhancements

RADAN CAD/CAM is a key area where click habits have been reviewed and advanced for simpler use – saving time and refining business processes. Part preparation is a time-consuming task and some operations have been reduced from two clicks to one, to apply settings.

Nest Mode | Grab Part

The Grab Part In Nest mode function, to change a part in nesting mode, has also been simplified saving average users an estimated minimum of 50 clicks per day.

Material Cost Saving

2019 R1 also provides material cost saving through importing remnants via the Raster to Vector function, and a stronger web option. Import a remnant via Raster to Vector can be used to eliminate wasting expensive remnants, such as specialised metals which can’t be scrapped. Users can now take a photograph of the sheet and bring it into the CAM system, giving the approximate dimensions, to use later. The system then draws a remnant with that shape cut out and you can use it again.

Batch Nest Function Enhancements

The Batch Nest function now benefits from a stronger web option which allows parts to be nested evenly across a sheet. This is optimised for the best cut option, where nothing else will fit on the sheet, and is particularly useful to stop sheets moving on punch presses, while preventing heat build-up on lasers by ensuring an adequate space between parts.

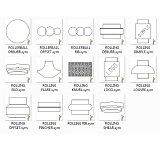

Radbend Updates

Three important updates feature in Radbend, including: improved automatic fingerstop positioning for sharp-angled parts; pre-selection of the bend process depending on the tool selection; and filter tool profiles.

Filter Tool Profiles: While every tool purchased is in Radbend’s tool library, it can also now show tools filtered according to manufacturer. It also shows all the tools capable of producing the required bend. To reduce that list even further, you can set additional filters. ‘Available,’ is for all tools in the system; ‘Valid’ are tools that would fit the job; and ‘Mapped’ shows tools which are already programmed and ready to go onto a specific machine. Mapped tools are particularly valuable for identifying what tool is available on which machine and in saving time, as setting up a tool involves measuring, and maybe even carrying out test bends, which can take around 20 minutes.

Radm-ax Updates

Radm-ax developments include automatic heat avoidance, hazard avoidance and common line cutting. A new cutting sequence for heat avoidance has been added to prevent heat build-up in the component. Improvements to hazard avoidance, calculating a better and safer path around hazards, and an increase in the ability to cut more difficult angles, such as 30-degree angles, with common line cutting, will also benefit production times.

RADAN Versión 2018 R2

RADAN Version 2018 R2

General

RADAN CAD/CAM 2018 R2 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD | Import and Export

This version of the software supports import of Inventor 2018, Solid Edge ST10, SolidWorks 2018.

2D CAM | Setup Sheets

All setup sheets data is now available in nest project reports; this enables the user to issue a complete pack of information to the shop floor with one click.

Part Pickers

RADAN 2018 R2 now has improved support for part pickers with symmetrical arms.

Grid Nesting

A new feature in manual nesting allows the user to quickly place down rectangular grids of parts.

Reverse Cutting Direction

In certain situations, the cutting process can be improved by reversing the cutting direction on a part. This can now easily be achieved using a new function in RADAN 2018 R2.

Radquote Purchased Parts

Radquote now offers full support for purchased parts. A purchased part can have a single purchase price set and any number of associated documents, such as PDF files and drawings.

Material Cost Options

The user can now choose from three different methods for calculating the material cost of a sheet metal part. In addition, all options are shown clearly with their associated cost.

Automation

New automation options allow parts to be automatically generated from CSV files third party geometry files. This can be used when importing quotes and orders into the system and it greatly shortens the process involved.

Batch Bending

Radpro 2018 R2 can now automatically process 3D parts for multiple press brakes. This automates all steps from import, sequence calculation, to generating the NC programs.

Radbend | Automation

To support batch bending, but also to offer greater flexibility to the user, it is now possible to specify the automation settings per machine tool.

DIN Unfolding

Radbend 2018 R2 now allows DIN values to be applied to sharp bends on parts. This is most important when the result radius differs from the design radius, where the design intent isn’t clear.

Radm-ax/Radtube | Common Cutting

Radtube 2018 R2 now supports common line cutting for tubes, to optimise material usage and cutting time. The user can specify which end (or both) of a tube is suitable for common cutting.

Auto-Cut Review

A new screen has been added which allows the user to view and change cut properties before the tool paths are calculated.

Clone Change Points

The user can now duplicate change points very easily by copying the properties from an existing change point.

RADAN Versión 2018 R1

RADAN Version 2018 R1

GENERAL

RADAN CAD/CAM 2018 R1 is only available as a 64-bit version – it is not possible to install this version on a 32-bit operating system.

3D CAD

Import and Export

This version of the software supports import of Solid Edge ST9, Creo Parametric version 4.0, Inventor 2017, SolidWorks 2017, and Unigraphics NX 11 files.

Chamfered Holes and Unfolding

When unfolding 3D sheet metal parts, any chamfered or formed holes on flat sheets will be represented by two profiles. The smaller profile (the hole) will be output in the pen specified for inner profiles, while the larger profile will be output in the pen specified for forms.

Note that all holes on non-flat sheets will still be represented by a single profile.

PROFILING | Offcuts

The option ‘Rectangular Offcuts’ cuts the unused area on the sheet up into rectangular remnants, as specified using ideal widths, ideal heights and the minimum size.

A tight offcut preserves the unused area of the sheet as a single remnant.

PUNCHING | Offcut Control

For punching machines, it is now possible to auto order parts and offcuts separately in order mode, even when they use the same tools, by specifying separate window Punch commands in the auto order style. The window Punch command may now use the following options:

- 'Offcuts' means do the offcut tooling features

- 'No-offcuts' means do all tooling features except the offcuts

GENERAL CAM

When changing machine tool, the strategy (if applicable) and Standard Tool Loading file will be updated to their current values for the selected machine (or to MDB/system data-specified default values if they have not yet been set for the selected machine). The tooling (and annotation on a nest) for the selected machine will also be shown.

If the selected machine supports strategies then you can also change the currently selected strategy using the Change Strategy... button. If the Standard Tool Loading file has not yet been set for this machine then it will be updated to its MDB/system data-specified default value; if it has been set already, but to a value different to its MDB/system data-specified default value, then the software will ask whether or not to continue using the value already set.

NESTING | New Batch Mode

RADAN 2018 R1 now offers a new approach to nesting that focuses on optimising the utilisation across a batch of nests (multiple nests). The new option is currently only available for profiling machines and can be found in the Multi-Part Nesting dialog.

RADBEND

Merge Co-Aligned Edges

Automatic fingerstop selection has been changed to combine co-aligned edges into one combined edge, filtering out small notches and crossing perpendicular bend-zones. This will reduce the number of unwanted alternative positions and possibly create new positions that meet minimum length requirements.

Maximum Gap for Combining Faces

The options menu now has a setting to control the maximum allowed gap for combining the edges. This defaults to the smallest flat fingerstop positioning face on a fingerstop minus the minimum overlap.

Previously any gap would lead to separate positioning faces and could result in a not optimal fingerstop placement (left). Radbend 2018 now applies the default gap (30mm) and combines the edges into one positioning face allowing the fingerstop to be in the middle.

Minimize Z-movements

With option “Minimize Z-axis movements” on, the fingerstop selection will try to select the same fingerstop Z-axis positions for as any bends as possible. This will reduce the amount of Z-axis movements between bends. This can enhance the security and be helpful avoiding slow axis movements on some machines.

RADM-AX | RADTUBE

Saving Individual Files from Assemblies

New options are available when saving files from assemblies.

Review Detected Cuts

During Auto Cut a new window allows you to exclude cuts, assign properties and change technology to any group of cuts before the tooling is created.

RADPRO | Assembly Support

Assemblies are now supported in Radpro, and indicated on the parts list.

Assemblies can be created manually by:

- Adding subparts to a part - use the + button in the Assemblies tab

- CSV import - remember to set your configuration properly

- 3D CAD file import using drag and drop or via the import buttons

In some cases, 3D source files do not include separate files for the sub parts. When this is detected we create SAT files for each part and assign them to the sub parts. This means you can continue to process the files with minimal fuss.

RADAN Versión 2017

RADAN Version 2017

Radmanager’s strength is that it creates nests without the user necessarily needing to know where the parts come from, what the order numbers are, or which customer they are for.

“In RADAN 2017, Radmanager’s ability to manage both 2D and 3D engineering of parts is the precursor to the entirely new forthcoming engineering system for any type of parts, including 5-axis laser-cut sheet metal, tubes, flat, and bent.”

The forthcoming Radquote, which is now available as a preview will be demonstrated at exhibitions and pilot customer sites ahead of its official launch. Radquote will also rely on engineered parts.

2D CAD files can also be imported automatically into Radmanager now, without the need to convert them.

CAD/CAM Updates

RADAN 2017 addresses danger of scrap flying off, sliding under the sheet, or damaging the tools on punching machines, by flagging up where floating scrap will occur.

The Automatic Order Style Editor now shows graphically what the program is going to do, enabling users to home in on a particular operation to make changes. This is seen as a major improvement on the previous text-based system.

Still with punch presses, RADAN 2017 configures machine tools with all available cutting tools, so that new customers have commonly used tools immediately available.

3D

A side panel was introduced in a previous version of RADAN which aids navigation around complex assemblies, but there was still a need to travel between the two. A new facility in RADAN 2017 allows the user to stay with the model, and to immediately switch between front view, side view, top view etc.

The graphics drawing has been speeded up. As an example, Olaf Körner explains that in earlier releases, deleting all screws in an assembly may take a while after they were selected, but now he says the software will always deliver a quick and consistent frame rate. The 3D function also supports modern graphics cards more efficiently, improving performance on tablets.

The process of updating information between Radbend and RADAN 3D has now been automated. “A design is analysed in Radbend, and then the bend information it provides fed back into the 3D model. This used to be a process that the user performed in a number of steps. Now, once the part has been identified, it’s a simple mouse click to update the information.”

Nesting

Improved algorithms have led to an important enhancement of RADAN’s powerful nesting capabilities. “Continuous effort is applied to further strengthen the nesting engine to achieve a better fit, and therefore, a potentially better material yield.”

With an increasing number of users adopting project nesting, a new reporting engine ensures users can easily customise the content and design of their reports.

It is also easier now to create nest projects, thanks to the new template function. Olaf Körner says: “Existing project settings can be stored with a given name, and recalled at any time. “Even creating nest projects for the same machine tool sometimes required repetitive work, but now everything the user needs will be there, saving quite a number of steps.”

Profiling

Autotooling routines are now more efficient in placing tags, or microjoints, for common cutting.

And the foil cutting function has been extended to scrap, ensuring that where sheets are covered with a protective foil for laser cutting, clean cuts can be made for scrap, too.

Radbend

Radbend now highlights where holes are at risk of deforming by being close to bends.

Also, the operator can switch between Design and Result Values. “This is particularly valuable where Radbend shows the end result of a radius, for example, may be different from how it’s designed. Selecting which values gives the user more control over the finished bend, depending on whether it’s vital that they stay with the design values, or if the end result values are acceptable.”

For the first time, the user can now check with different maximum allowed force for the pre-bend and the hemming operation done with same tools.

Improved communication between 3D and 2D parts ensures that Radbend can now link to the 2D flatblanks created by RADAN 3D. It also means that with more information going to the flatblank, 2D bends can easily be seen – the tooling and sequence number, as well as the radius, angle and setback.

Also, Radbend now supports the new user interface, Touchpoint TruBend, which combines the advantages of multi-touch technology with industrial control…as all Trumpf pressbrakes will move to this state-of-the-art controller.

Radtube

While Radtube has traditionally been used for simply cutting tubes, it can also program any extruded shape for tube cutters, including I-beams, H-beams and C-beams, along with L-shaped profiles. “Because cutting a round or square tube is completely different from working with more complex beams and profiles, we’ve assisted the user with this by vastly improving automation and support.”

Summing up RADAN 2017, Olaf Körner says the items of new and enhanced functionality provide immediate improvements for sheet metal manufacturers, while underlining the intention to continue investing heavily in the software.

RADAN Versión 2016

RADAN 2016

General

3D CAD:

Import and Export

3D Side Panel

The panel can show the contents of the model as a list or as a tree, showing the assembly structure if present. In Selection mode, parts selected in the side panel are highlighted in the 3D window and parts selected in the 3D window are selected in the side panel. The user can perform a number of actions from the side panel, including delete, change name, material and visibility.

Profiling:

Open Profiles

Cutting Conditions

Punching:

Automatic Tooling Mode

Importing Settings

2D Geometry:

2D Import

Raster to Vector

NEW SETUP SHEETS:

XtraReports

In RADAN CAD/CAM 2016, the user can use a new WYSIWYG report design to tailor the information on machine setup sheets to suit the exact needs. The reports can include graphics, charts, bar codes and QR codes and the designer is easy to use with a short learning curve.

RADBEND:

Minimum Flange Definition

Radbend 2016 has improved handling for small flanges. The calculations used to determine the minimum flange length that can be bent with a die have been improved. When the user manually selects a die and the software detects that the flange to be bent is smaller than the minimum length allowed for the selected die, the message shown explains this clearly.

Automatic Tool Changer (ATC) Support

Radbend 2016 further improves on the support for LVD TOOLCELL machines, allowing a nominal gap to be introduced between the tool parts.

Manual Tool Selection “Heel tool usage”

The new options/status in manual tool selection shows usage of heel parts and angle measurement parts. The user can force the usage of heel tools and or 1, 2 or 3 measurement tool parts while entering the required length and apply.

Unfold values for Hemming

Unfold values for hems are not easy to setup in bending tables in CAD systems because the process is quite different from air bending. Setback is undefined for 180 degree hem bends and neutral axis values can’t be extrapolated for (very) small radii. In Radbend 2016 you can setup unfold values based on values found in practice but independent of specific designed radii.

RADAN Versión 2015

RADAN Ultima Versión 2015

CAD 3D:

Importar y Exportar

Precisión

Cara Superior

Para ayudar en la automatización, el usuario ahora puede especificar la ‘cara superior’, es decir, la cara que se considera la superior durante el proceso de corte y del plegado.

Plano para Plegar

El módulo plano para plegar se ha mejorasdo significativamente para usar propiedades de geometría extendidas para el análisis del planio en blanco y un proceso más directo para crear la pieza 3d final desde la geometría 2D.

Punzonado:

Estaciones de Herramientas

Deformación de la Lámina

Ciclos Fijos Automáticos

Esta versión permite a los usuarios hacer uso de los ciclos fijos de máquina de forma más automática para reducir el uso de memoria de un programa.

Perfilado:

Entradas Undercut

Evitación de Calor

Anidado:

Anidado Rectangular

Optimización

Tratamiento del Material:

Carga de Láminas

Se ha mejorado de forma significativa el soporte para los dispositivos de carga de láminas y la carga manual de láminas.

Retirada de Piezas

Se ha mejorado el soporte para los dispositivos de retirada de las piezas como recogedores de piezas para realizar más chequeos de validación para asegurar una retirada más segura y fiable de las piezas y del material de desecho.

RADBEND:

Control del Sistema:

Radbend ahora ofrece al usaurio nuevas herramientas de configuración mediante el interfaz de usuario para optimizar más los procesos de plegado.

Tecnología

La creación y el tratamiento de herramientas heel tools se ha hecho que sea más intuitivo y Radbend ahora ofrece más control sobre el proceso de dobladillo (engatillado).

RADAN Versión 2014

RADAN Versión 2014

3D CAD:

Importar y Exportar

Desplegado Automático

2D CAD:

Patrones en una Ventana Dividida

Propiedades Geométricas Especiales

Autotooling:

Cortes de Descarte en Aperturas

Herramientas en Racimo o Agrupadas

Piezas con Corte Común

Tooling:

Herramientas de Rueda Asimétricas

Corte de Lámina

Anidado:

Corte por Línea Común

Las opciones para el Corte por Línea Común en el diálogo de Anidado Multi-Pieza, que anteriormente estaba disponible sólo para las máquinas de perfilado, ahora están disponibles también para las punzonadoras.

En el anidado manual, la casilla 'Corte Común' ahora está disponible al ubicar piezas en la anidación tanto para las punzonadoras como para las máquinas de perfilado. El diálogo de Luces para el Anidado Manual permite el cambio de la anchura del hueco para corte común.

Estado del Flujo de Trabajo

Los nuevos iconos de estado informan al usuario de las tareas pendientes al anidar y preparar las piezas, haciendo que el flujo de trabajo en RADAN sea más intuitivo y mejorando la eficiencia automatizando las tareas obvias.

Programación NC:

Gráficos e Interfaz de Usuario

Al preparar un programa NC en RADAN 2014, el usuario está asistido por gráficos actualizados y nuevos modos de visibilidad que aumentan mucho la eficiencia y la información. Los cambios en los ajustes se reflejan de forma inmediata en la vista actual ofreciendo mayor seguridad para los programas complejos y un interfaz más intuitivo para los usuarios nuevos y los ocasionales.

Otra serie de cambios ofrecen una apariencia más ‘amigable’ a la información en detalle, facilitando la adaptación al software.

Simulación

Haciendo un uso completo de los gráficos mejorados, el nuevo modo de simulación permite una investigación más detallada de la secuencia de corte, además de una visión general rápida y fluida sobre cómo se procesará la lámina.

Estimación de Tiempos

La nueva tecnología en RADAN 2014 asegura una estimación de tiempos a partir de los nuevos postprocesadores y de los re-configurados para obtener una significativa mayor precisión que la que era posible anteriormente.

Instalación:

Se ha reemplazado el programa que instala el software en un servidor y en un ordenador cliente.

.jpg)

.jpg)